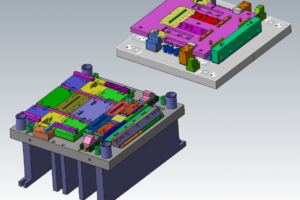

Dekalb Tool & Die has over 50 years of experience designing and programming tooling for the metalworking industry. We create a wide range of reliable products, including transfer dies, progressive dies, line dies, draw dies, and changeover tooling. Our fully-equipped die shop features everything needed to develop complete new tooling packages, perform emergency repairs, or reverse engineer an existing product.

Tool and Die Key Features

As a one-stop provider of tool and die services, Dekalb offers everything your project needs under one roof, including die design, tryouts, metal stamping, and die repair. We serve a broad range of industries, including automotive, aerospace, lighting, HVAC, consumer goods, and more. Our tool and die services provide industry-leading features, such as:

- Precision: We meet tolerances of +/- 0.001 in.

- Durability: Maximum durability is achieved through robust design and proper material usage.

- Versatility: Our skilled design and engineering teams develop solutions for virtually any industry and application, large or small.

- Customization: Products that require tools and dies are unique and commonly custom-designed. We can reverse engineer an undocumented existing design or work with you to develop a new die that meets all of your specifications.

- Efficiency: Our team works efficiently to produce high-quality tools and dies cost-effectively and according to your required time schedule. We also offer emergency repair services.

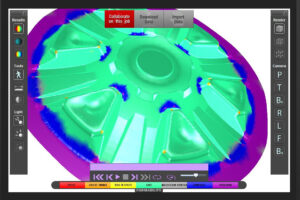

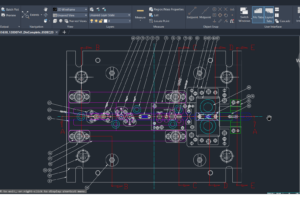

- Innovation: We use state-of-the-art 3D and 2D design processes and incorporate the latest technology to bring innovation to our customers.

- Collaboration: Our in-house design team, skilled machinists, and engineers work together to ensure your final product meets all of your specifications.

Applications of Tools and Dies in Manufacturing

Applications throughout many industries use tools and dies. Some of the most common end-uses for our products include:

- Stamping and forming: To produce autobody parts, electronic components, and appliances

- Cutting and shaping: To cut materials such as metals and plastics into precise shapes and sizes

- Drawing and stretching: To produce wires, cables, and springs

Tool and Die Stamping From Dekalb Tool & Die Inc.

No matter what your project entails, our knowledgeable team is equipped to meet your needs. Our ISO-certified facility features an overhead crane with 30-ton lifting capabilities and forklifts that handle up to 30,000 lbs for jobs with large tooling. For challenging parts and prototypes, our access to Draw Simulation, hydraulic press, and 5-axis laser ensure your end component meets all of your specifications. When your project is completed, we handle regional deliveries with care using our own fleet of flatbed and dry van trucks.

To learn more about our tool and die stamping capabilities, contact us or request a quote today.

Design & Build

Engineering

- Master Cam 3D CAD/CAM

- Vero VISI 3D CAD

- Autrocad 2D

- HP Design Jet T730

- E-Size Roll Feed Plotter

Quality Control

- Keyence XM 5000 Coordinate Measuring

- 48” x 96” Granite Surface Plate

CNC Mills

- Mori Seiki MV65 Vertical CNC Mill 25” x 25” x 60”

- Fadal VMC 6030 Vertical CNC Mill 30” x 30” x 60”

- Fadal VMC 4020 Vertical CNC Mill 20” x 20” x 40”

- G&L Horizontal 4-Axis CNC Mill 38” x 35” x 107”

- G&L Horizontal 4- Axis CNC Mil 35” x 72” x 132”

WEDM

- Sodick AQ327L 14.3 x 10.3 x 8” Z

- Sodick AQ535L 14” x 21” x 11” Z

Conventional Mills

- Kearny & Trecker S-15 Horizontal

- 5” G&L 340-T Boring Mill Horizontal

- #5 Kearney & Trecker Vertical

- (7) Bridgeport Mills

Lathes

- 20” x 96” Lodge & Shipley

- 16” x 60” Monarch

- 14” x 48” LeBlond

- 12” x 48” Clausing

Grinders

- Mattison 60” Dia. Rotary Surface Grinder

- Okamoto 16” x 32” Surface Grinder

- Okamoto 12” x 24” Surface Grinder

- Gallmeyer 12” x 36” Surface Grinder

- Brown & Sharp 12” x 24” Surface Grinder

- (5) Harig 6” Surface Grinder

- Boyar Schultz No @ Profiele Grinder

- Medina End Grinder

- Gardner 24” Dia. Double End Drum Sander

Press Brake/Shear

- 8’ Dreise & Krump Brake

- 10” Edwards LTD Brake

- 3/16” x 12’ Columbia Shear

Heat Treating

- 12” x 18” x 26” Atmosphere Controlled Furnace

- 12” x 18” x 26” Draw Furnace

- 10” x 10” x 22” Furnace w/ 10”: x 10” Draw

- Rockwell Hardness Tester

- Dry Blast and Glass Bead Blast

Saws

- Johnson Cut off Saw

- 24” Powermatic Band Saw

Miscellaneous

- (12) Overhead Cranes 2Tons to 30 Tons

- Fork Trucks from 3000lb to 35,000 lbs Capacity

- Sunnen Hone

- Various Weld Equipment MIG & TIG/ 250 -400 Amp