Dekalb Tool & Die is a leading provider of metal stamping services with over 50 years of experience delivering a wide range of solutions to more than 10 different industries. As an ISO 9001:2015 certified manufacturer, our team provides knowledgeable engineering support and in-house die maintenance to ensure our clients receive quality stampings on time.

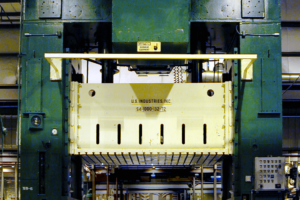

At Dekalb Tool & Die, we’re equipped with 20 presses ranging from 55 to 1,800 tons. Our largest progressive stamping line is 800 tons with a 144” press bed and coil capacity of 30,000 pounds. We have five smaller progressive lines ranging from 60 to 400 tons. The 1,100-ton hydraulic press has a bed size of 84” by 120” with about 12” of cushion travel for large draws and SSDC capability to 1,000 tons.

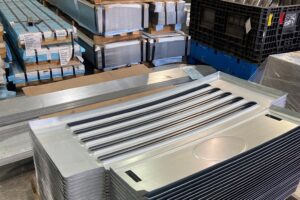

Dekalb Tool & Die can accommodate high-volume and low-volume production programs. We also have experience in multiple material types and grades, including mild steel, galvanized, pre-paint, high strength low alloy, stainless steel, aluminum, brass, and plastic. Learn more about our metal stamping capabilities here.Met

Metal Stamping Key Features

At Dekalb Tool & Die, our metal stamping capabilities are designed to offer a full-service solution to our valued customers. Here are some of the key features and benefits you’ll enjoy if you work with us for your metal stamping needs:

- Die maintenance & repair: Our stamping operations are backed by comprehensive in-house die maintenance and repair services.

- Variety of stamping types: Our expertise covers a range of stamping operations, including progressive, single hit, line dies, and draw dies.

- Diverse industry experience: We have extensive experience providing metal stamping services for industries such as aerospace, automotive, heavy truck and bus, HVAC, home goods, outdoor products, recreation, satellite communications, lighting, and commercial refrigeration.

- 5-axis laser technology: We employ 5-axis laser technology to trim large or low-volume stampings after they are formed. These services are ideal for jobs that require trimming after forming but come in order quantities too low to justify tooling.

- ISO 9001:2015 certification: Our ISO 9001:2015 quality registration shows our commitment to high-quality standards demanded by every industry.

- Regional deliveries: We offer regional delivery with our fleet of flatbed and dry van trucks.

- Production assistance: We offer long-run, short-run, or contingent-run programs to assist customers in cases of equipment failure or capacity issues. We are capable of maintaining production while accommodating design modifications through engineering changes.

- Decades of experience: With over 50 years of experience in metal stamping, our team provides engineering support that addresses our customers’ exact needs.

Industries That Utilize Metal Stamping

Dekalb Tool & Die’s metal stamping process produces high volumes of identical metal components to exacting customer requirements across a wide range of industries including:

- Automotive

- Aerospace

- Agriculture

- Construction

- Home Goods

- Healthcare

- Home appliances

- Lighting

- Large truck and bus

- Commercial Refrigeration

- Recreation

- Furniture

Metal Stamping From Dekalb Tool & Die, Inc.

Dekalb Tool & Die, Inc. is a reliable and trusted provider of metal stamping services for various industrial production projects. Partner with us for efficient and cost-effective metal stamping services that leverage our extensive capabilities, dedication to quality, and commitment to customer satisfaction. Whether you need long-run production, short-run orders, or assistance during unexpected equipment failures, our dedicated team can help.

Request a quote to get an estimate for your project or to learn more about our capabilities.

Stamping

- [1] 1800 Ton Warco Double Action SSDC 96” x 136”

- [1] 1100 Ton Tranemo Hydraulic 84” x 120”

- [1] 1000 Ton Clearing S.S.D.C 96” x 132”

- [1] 900 Ton Hamilton S.S.D.C. 120” x 186”

- [1] 300 Ton Minster S.S.D.C. 48” x 96”

- [1] 300 Ton Toledo S.S.D.C 48” x 120”

- [1] 300 Ton Bliss S.S.D.C. 54” x 120”

- [1] 300 Ton Taylor Winfield 60” x 120”

- [1] 200 Ton Bliss S.S.D.C. 36” x 84”

- [1] 90 Ton Niagara OBI

- [1] 60 Ton Roussel OBI

- [2] 55 Ton Federal OBI

Progressive Lines

- [1] 800 Ton Blow S.S.D.C 72” x 144”

60” Wide Servo Feed

30,000 lb Coil Max - [1] 300 Ton Minster S.S.D.C. 60” x 54”

24” Wide Servo Feed

20,000 lb Coil Max - [1] 300 Ton Minster S.S.D.C. 60” x 48”

48” Wide Servo Feed

20,000 lb Coil Max - [1] 350 Ton Clearing S.S.D.C. 50” x 84”

24” Wide Servo Feed

20,000 lb Coil Max - [1] 60 Ton Bliss OBI. 20” x 36”

6” Wide Servo Feed

3,000 lb Coil Max

Turret Punch

- Strippit LVD Delta 1000 20 ton