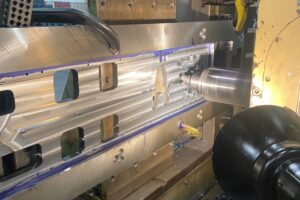

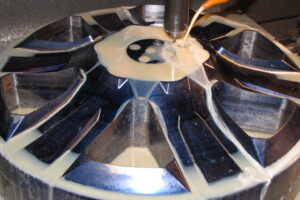

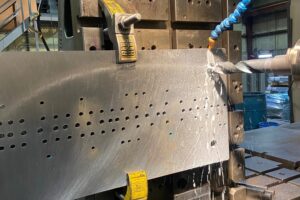

Dekalb Tool and Die utilizes computer numerical control (CNC) milling and 5-axis laser cutting to enable high-volume manufacturing and rapid prototyping of high-precision parts and products. As the name suggests, CNC milling uses a computer with software that controls the cutting tools of the milling machine. The process offers high accuracy, precision, and production rates.

Five-axis laser cutting processes components on five axes and allows the headstock to tilt and rotate. This process also creates complex parts efficiently and accurately. Learn more about the benefits and applications of each technique employed by Dekalb Tool and Die to determine the right one for your needs.

Benefits of CNC Milling & 5-Axis Laser Cutting

Benefits of CNC Milling

Dekalb Tool and Die’s advanced CNC milling services are utilized across a wide range of industries including, aerospace, agricultural, automotive, food and pharmaceutical. Some of the benefits of Dekalb Tool and Die’s advanced milling capabilities include:

- Superior Build Volume: We offer both three axis Vertical and Horizontal Machining Centers with a vertical tooling capacity and a 30″x30″x63″ work envelope, as well as horizontal boring mills possessing a 38″x132″x72″x35″ work envelope.

- Greater Accuracy: Our precision milling machines eliminate manual intervention and thus the risk of human error. The G-code controls the process from beginning to end allowing us to meet tolerances to within .001” in order to satisfy high industry standards and achieve ISO compliance.

- Faster and Efficient Production: Our CNC machines can operate quickly and efficiently to meet high-volume production demands. They also do not require rest breaks and can run continuously for long periods.

- Wide Variety of Machined Metals: At Dekalb Tool and Die we offer the ability to machine any number of materials including mild steel, steel alloy, aluminum, cast iron, bronze, and plastic.

Benefits Of 5-Axis Laser Cutting

Dekalb Tool and Die’s superior 5-axis laser capabilities have produced a wide range of products across a multitude of industries including aerospace, tool and die building and repair, electronic manufacturing, as well as semiconductor manufacturing. Whether it be architectural ornaments, HVAC, tubing, or general sheet metal fabrication our ISO and TS compliant laser cutting operations can meet your industry’s most precise tolerances. The advantages of Dekalb Tool and Die’s 5-axis laser expertise include:

- Accuracy and Precision: Our 2000 and 4000 watt capacity full 5-axis lasers minimize machining errors for more accurate, repeatable cuts to very close tolerance.

- Complex Designs: Our 5-axis laser cutting machines offer an increased range of motion and position of the beam. While 2-axis machines can be used to cut flat sheet material and 3-axis machines can be used to cut three dimensional parts, our 5-axis machines can perform the functions of both as well as laser cutting operations on parts that have been pre-formed by casting or machining.

- Higher Speed: Our Flying Optics Laser will allow the cutting of the whole workpiece in a single step. This laser configuration features a stationary table and a cutting head that moves over the work piece in both of the horizontal dimensions. Flying-optics cutters keep the workpiece stationary during processing, and often don’t require material clamping equipment thus eliminating the need for multiple operations or setups, leading to faster output capacity.

- Excellent Finishes: The machine’s fourth and fifth axes position the beam perpendicular to the part surface for exceedingly clean cuts.

- Superior Capacity: Our state-of-the-art 5-axis CO2 lasers can accommodate all but the largest jobs inside of a 122″x 87″x 33″ work envelope as well as operate on a broad array of materials including both ferrous and non-ferrous metals.

CNC Milling & 5-Axis Laser Cutting by Dekalb Tool & Die

CNC milling and 5-axis laser cutting techniques provide reliable and efficient solutions to many complex problems that traditional machining methods cannot solve. These two machining processes are widely accepted in part and component manufacturing for their precision, accuracy, and tight tolerances.

At Dekalb Tool & Die, Inc., we offer high-quality machining services, including CNC milling and 5-axis laser cutting. Our experienced engineers can help you decide which method is right for your application and can create the exact parts and products you need. Request a quote to start your project and get an estimate.

5-Axis Laser

- Mitsubishi VZ1 5-Axis

- 2000 Watts

- Travel 122” x 87” x 33”

- Mitsubishi VZ20 5- Axis

- 4000 Watts

- Travel 122” x 87” x 33”

- Coming in 2024

- Trumpf 5030 L80 Fiber Laser

- 4000 Watts

- Max Workpiece

- X 2540 mm

- Y 1040 mm

- Z 470 mm